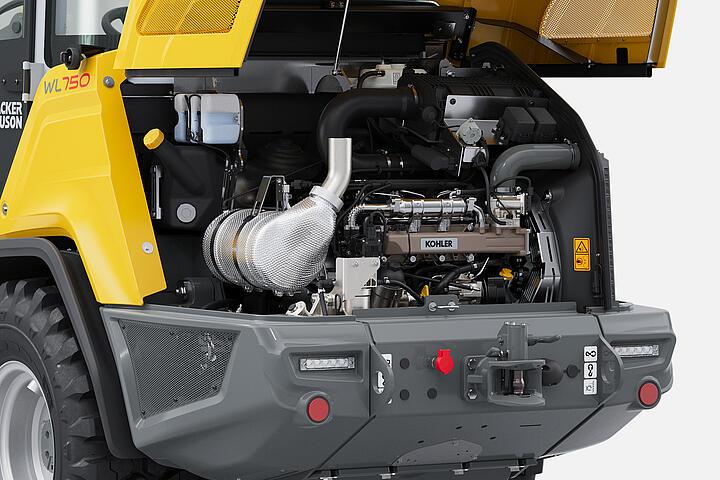

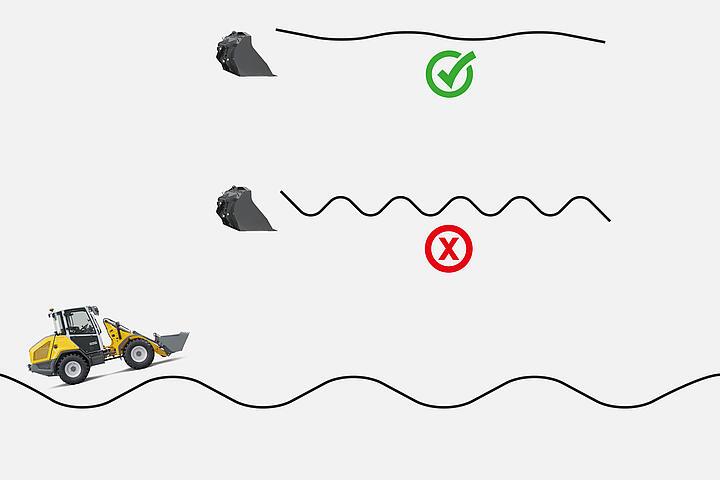

These features characterize the WL750 wheel loader: Comfort cab with excellent ergonomics and all-round visibility, electronically controlled travel drive with various travel modes, robust loader arm with the best view of the attachment, wide range of options and a modern machine design. The transversely installed motor and the optimized arrangement of components ensure very good maintenance accessibility. The WL750 is the ideal entry-level model in the wheel loader class with 0,75 m³ bucket volume. It combines power, reliable hydraulics and compact dimensions with sophisticated technology and a convincing price-performance ratio.